Successful Implementation of Innova’s multiplexer for a Triton XLX Upgrade Package

The custom Triton XLX upgrade package was developed in close cooperation with our customers to replace legacy fiber-optic stacks in subsea and surface vehicle control systems. The design philosophy focused on reliability, ease of installation, and minimal wiring requirements. Key criteria included atmospheric mounting of electronics, emulation of legacy system connections, and the use of…

Control System for subsea Mattress Retrieval Tool (MRT)

The project was executed by a multidisciplinary team, including mechanical, software, and electrical engineers, supported by skilled mechanical and electrical technicians for the assembly and testing of the valve packs. Each valve pack featured 5 proportional and 3 on/off NG10 valves, pressure sensors, and a water ingress sensor, housed in an aluminium manifold and POM…

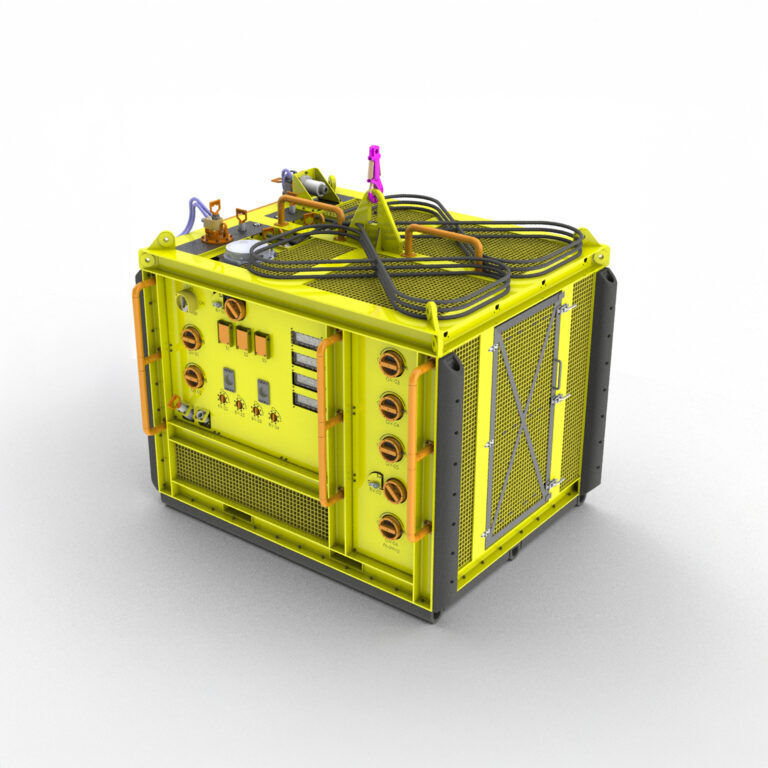

Control System for Diamond Wire Saw

Our team of mechanical, electrical, and software engineers developed a customized 3-channel NG10 Subsea valve pack system designed to control the hydraulic systems of diamond wire saws at depths of up to 3000 meters. Key features included: A custom GUI was developed for the laptops, providing real-time control and monitoring tailored to the operational needs.…

Control system for Underwater Pipe Repair Tool

Upon securing the contract, Innova leveraged its existing building blocks and innovative expertise to create an advanced control system tailored to the client’s needs. This included a hydraulic power unit, instrumentation, and a controller unit, all designed to enhance operational efficiency. Some of the necessary components were not available on the market and had to…

Fluid Sampling Skid

In spring 2024 Innova delivered Fluid sampling skid, which was co-developed with our customer. The skid is a stand-alone subsea skid designed to take samples from up to 6 wells and separate the phase to obtain pure water samples for further analysis in laboratory. The customer requires to perform ion- and residual scale inhibitor analyse…

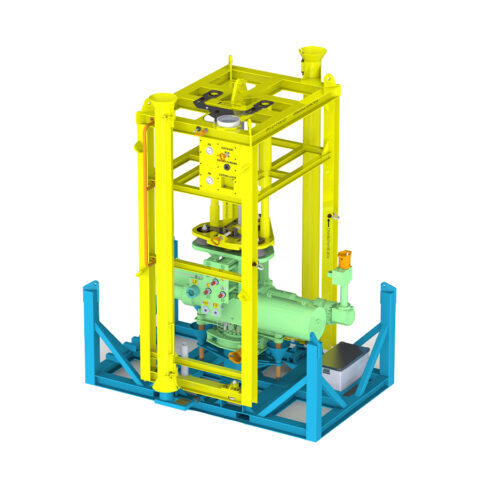

Actuator Running Tool (ART) – horizontal

ART is designed to retrieval and installation of tool will be deployed to the SSIV structure seabed and positioned over the actuator on a subsea pipeline and enable a quick and safe replacement of an actuator valve in case of failure. The delivery consisted of Actuator Running Tool and two transportation skids. It was…

Electric Actuator for Small bore valve

An electric actuator for small bore valves was developed and successfully qualified to API17F by Innova during an extensive and challenging project.

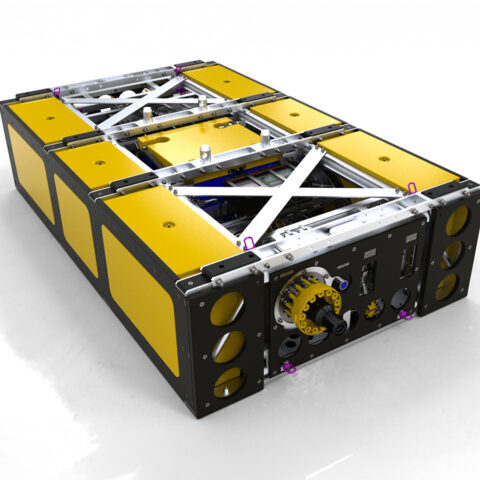

FlyWOCS

Innova designed, assembled and tested the FlyWOCS, starting with the concept phase and ending with mobilization and operational support. The skid involved multidiscipline effort, including mechanical, hydraulic, electrical and software engineering. Standard Innova components were vital in the design, though some propriety solutions were needed to create a fully seamless solution. The system is powered…

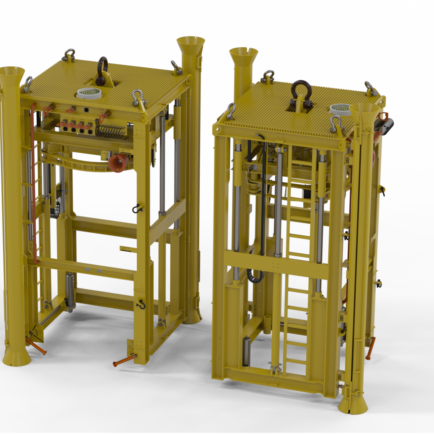

Actuator Running Tool

The Actuator Running Tool (ART) is designed and tested for retrieval and installation operation of subsea hydraulic actuators up to 10.500kg. The key features include a DNV 2.7-3 lifiting frame and an adjustement mechanism integrated. The Actuator Running Tool lands on a subsea structure using configurable guidepost and mini-guide posts for fine guiding. Integrated soft-landing…

Soft Landing Control System

The Soft Landing Control System was designed and delivered by Innova Aker Subsea to ensure controlled landing of the Åsgard Subsea Compression modules. Åsgard Subsea Compression is the world’s first subsea gas compression plant, and was put on-line by Statoil in 2015.