Case studies

Electric Actuator for Small bore valve

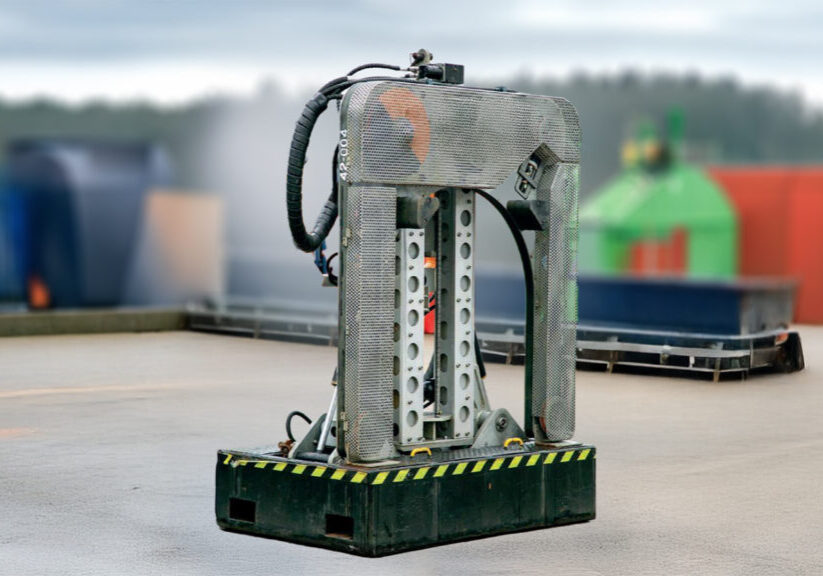

An electric actuator for small bore valves was developed and successfully qualified to API17F by Innova during an extensive and challenging project.

Category: Case studies

The actuator is developed for permanent installation (25 years minimum) subsea for control of small-bore valves, up to ½” bore size. The product contains motor controller and a power bank for failsafe action in case of loss of power or loss of communication. The operator can pre-set the desired state in the case, fail-safe close, open or as-is.

Team innovation

The development project of the Electrical Actuator included all engineering disciplines of Innova; mechanical, electronics and software, as well as ensuring the complete system would be working as specified on cross-discipline level. The design phase also included TRL, FMECA and RAM evaluations to ensure the proper quality of all the sub-components. A Motor Controller PCB and Power bank was designed and developed for this specific product.

Tests

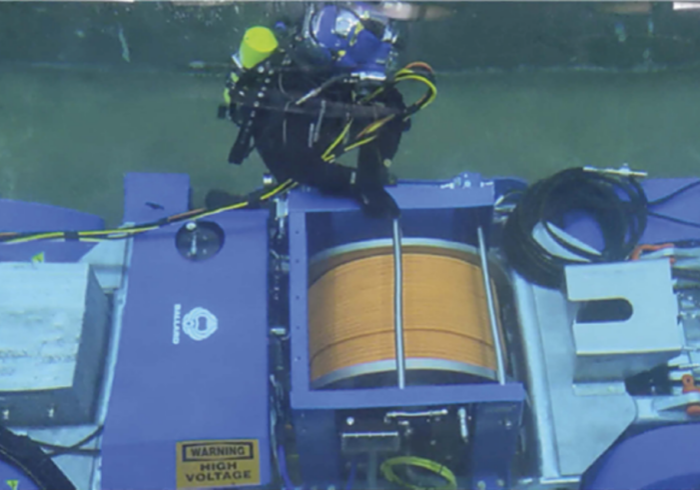

After the design phase followed a qualification phase with multiple tests that needed to be performed on component level but also on product level. All tests were performed according to the strict and demanding requirements of the well-known API17F standard. The test regime included:

- Q1, Shock & Vibration testing on PCB level

- Q1, Temperature, on PCB level

- Q2, Shock & Vibration, on product level

- Q2 Temperature, on product level

- EMC testing of complete product

- External hydrostatic testing, product level to 3000meter rating

Want to learn more?

Get in touch with us

For more information or requests call us on

+47 51 96 17 00 or send an e-mail to sales@innova.no.