Case studies

Fluid Sampling Skid

The Fluid Sampling Skid is designed for subsea use and operated by ROV assistance. It is autonomous, meaning it is self-powered and only needs interaction from ROV to initiate the different processes.

Client: ConocoPhillips

Category: Case studies

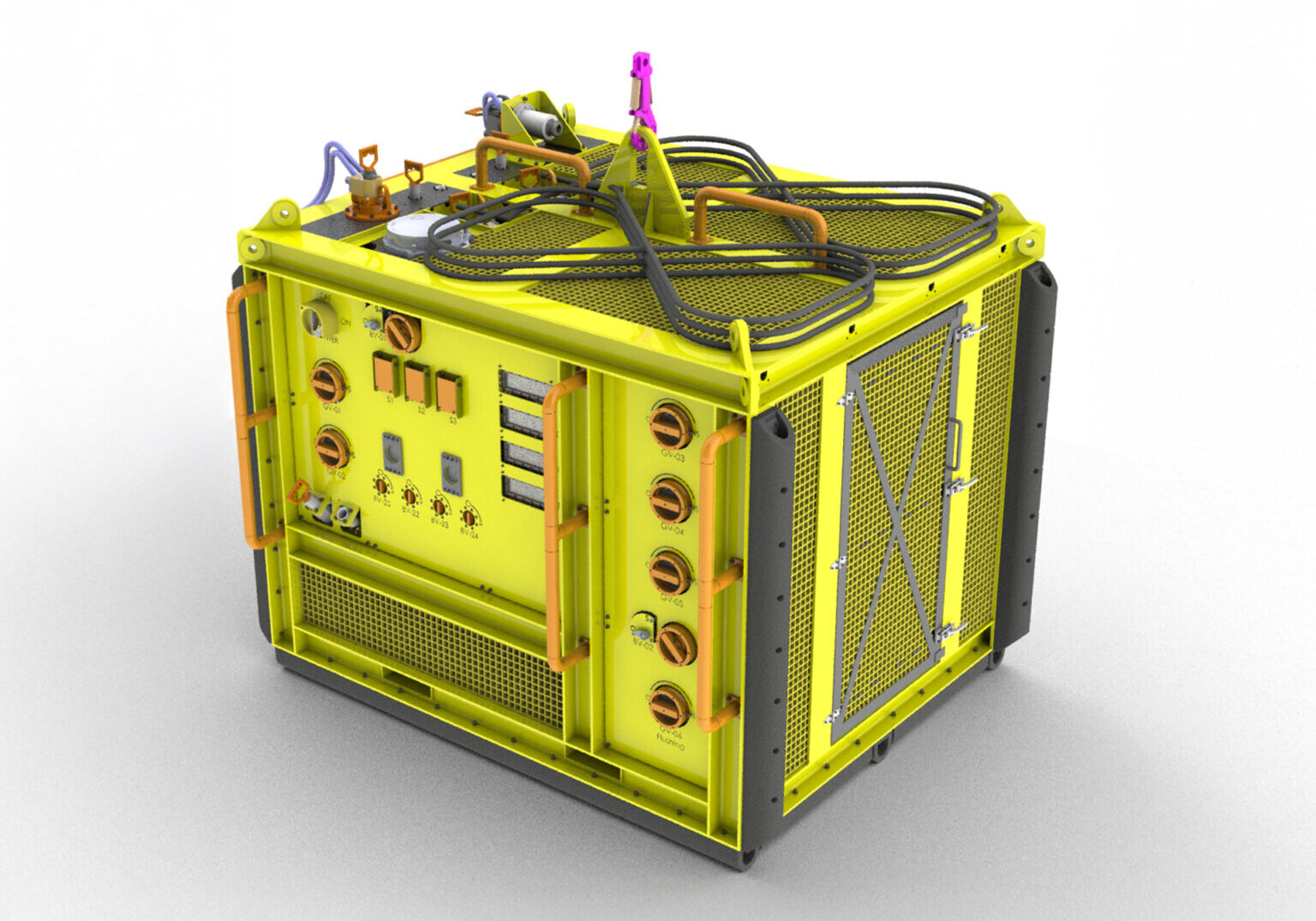

In spring 2024 Innova delivered Fluid sampling skid, which was co-developed with our customer. The skid is a stand-alone subsea skid designed to take samples from up to 6 wells and separate the phase to obtain pure water samples for further analysis in laboratory. The customer requires to perform ion- and residual scale inhibitor analyse of the sampled water to understand more of the situation in each well and to evalute the need for chemical injection. By collecting individual well samples, the precicion of the analysis is greatly improved compared to the conventional sample of multiple wells.

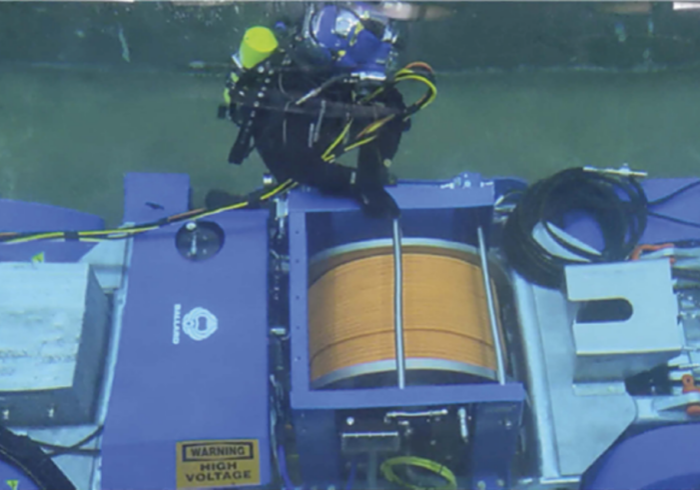

The Fluid Sampling Skid is designed for subsea use and operated by ROV assistance. It is autonomous, meaning it is self-powered and only needs interaction from ROV to initiate the different processes.

The system includes the following main elements:

- DNV 2.7-3 structure with subsea damper system

- Process equipment for circulation and separation of produced well fluids

- Water samples bottles suitable for sampling up to 6 individual wells

- Produced fluids waste bottles

- Preservation and displacement fluids bladder system with HP injection pump

- Battery powered control system including instrumentation and ROV displays and manometers

- Hose bundle with dual bore stab connection

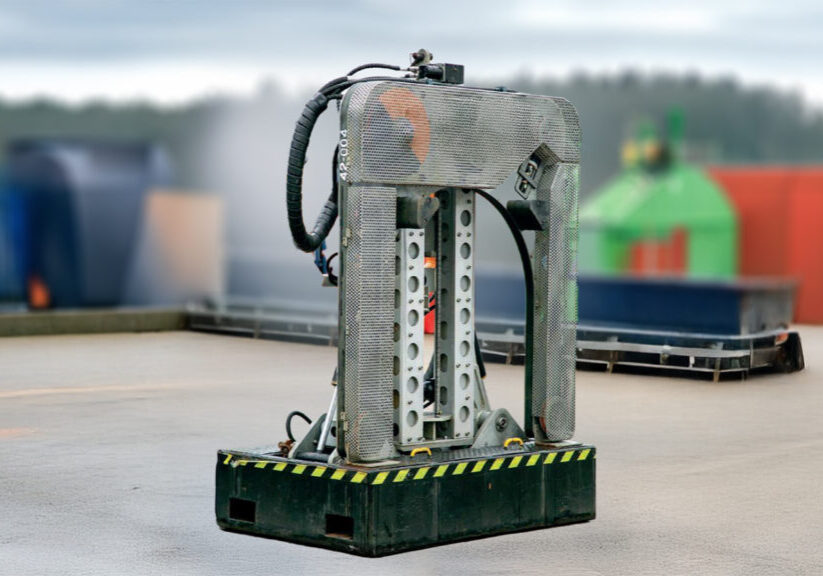

- Fluid Sampling Skid transport handling equipment (if not integrated in Fluid Sampling Skid)

- Transport skid with truck interfaces and offshore vessel grillage welding interfaces

- Single point lifting with forerunner for installation and retrieval subsea of Fluid Sampling Skid

- Landing location on manifold roof for Fluid Sampling Skid

- Dual bore receptacle on well Flow Control Module for connection of hose bundle and stab

- ROV panel for ROV valves operation and display panels on the Fluid Sampling Skid

- Topsides and vessel handling interfaces and weld to grillage

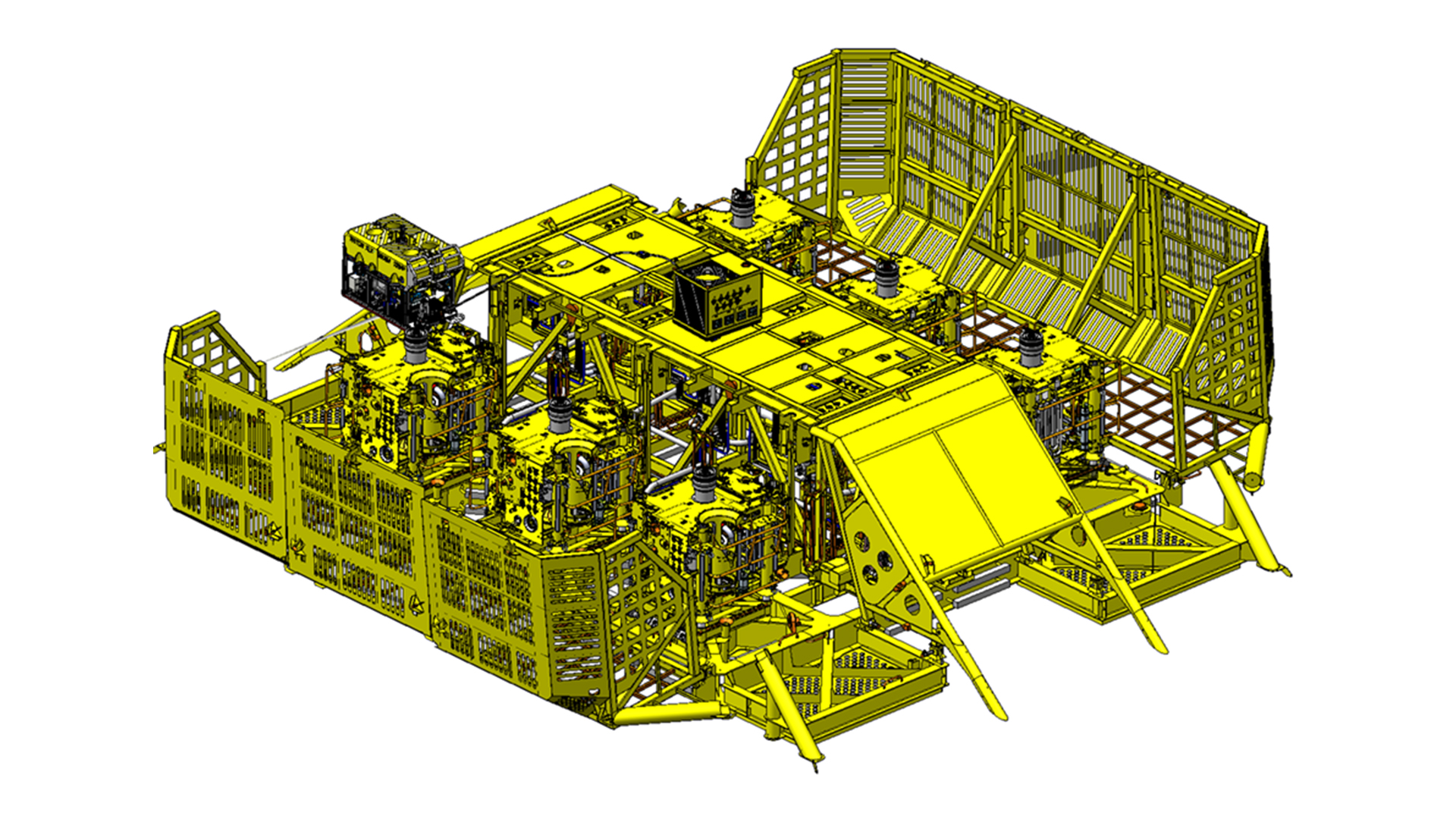

FSS and VXT

The system shall facilitate for sampling of production well fluids from upstream the production choke on the VXT. The sampling point in the VXT shall be facilitated and designed to enhance sampling of liquid phase fluids.

The system shall allow for circulation of the sample well fluids via a Fluid Sampling Skid with return of well fluids to downstream the production choke on the VXT.

It shall be possible to circulate fluids with a pressure drop across the VXT production choke in the range of up to 140 bar and down to 10 bar or less.

The system shall include for required barriers towards the production well stream in all phases of the sampling operation.

The Fluid Sampling Skid shall be designed with configurable and/or replaceable components to optimize the system towards the varying pressure drops across the production choke of life of field.

The Fluid Sampling Skid shall include for a separation process system in which by circulation collects available upstream water phase and gas phases in a dedicated separator vessel.

The water and gas samples shall be representative for each individual production well stream. As such contamination of oil and organic fluids immiscible with water shall be minimized. As such sufficient circulation and separation of water phase shall be ensured to provide representative samples.

Contamination of MEG in separated water shall be avoided as far as possible during the sampling phase (less than 1% MEG in water by volume). A dedicated MEG injection line from MEG bladder to

FCM piping for preservation shall be considered.

The Fluid Sampling Skid shall meet the following collet and allow for separate sampling of the following phases and volumes:

- Water sample for ion analyzes with a desired volume of 250 to 300ml, and minimum 20ml.

- Water sample for RSI (Residual Scale Inhibitor) analyzes with a desired volume of 50ml.

The samples shall be retrieved from subsea to topsides vessel with the Fluid Sampling Skid. The system is design for 2 samples of each production well. Average estimated sampling frequency for each well is 4 times each year.

Want to learn more?

Get in touch with us

For more information or requests call us on

+47 51 96 17 00 or send an e-mail to sales@innova.no.