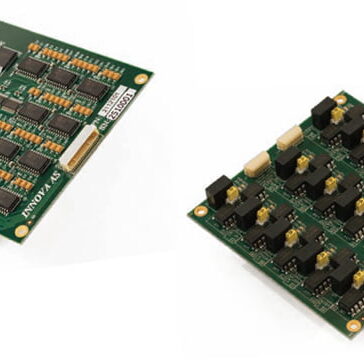

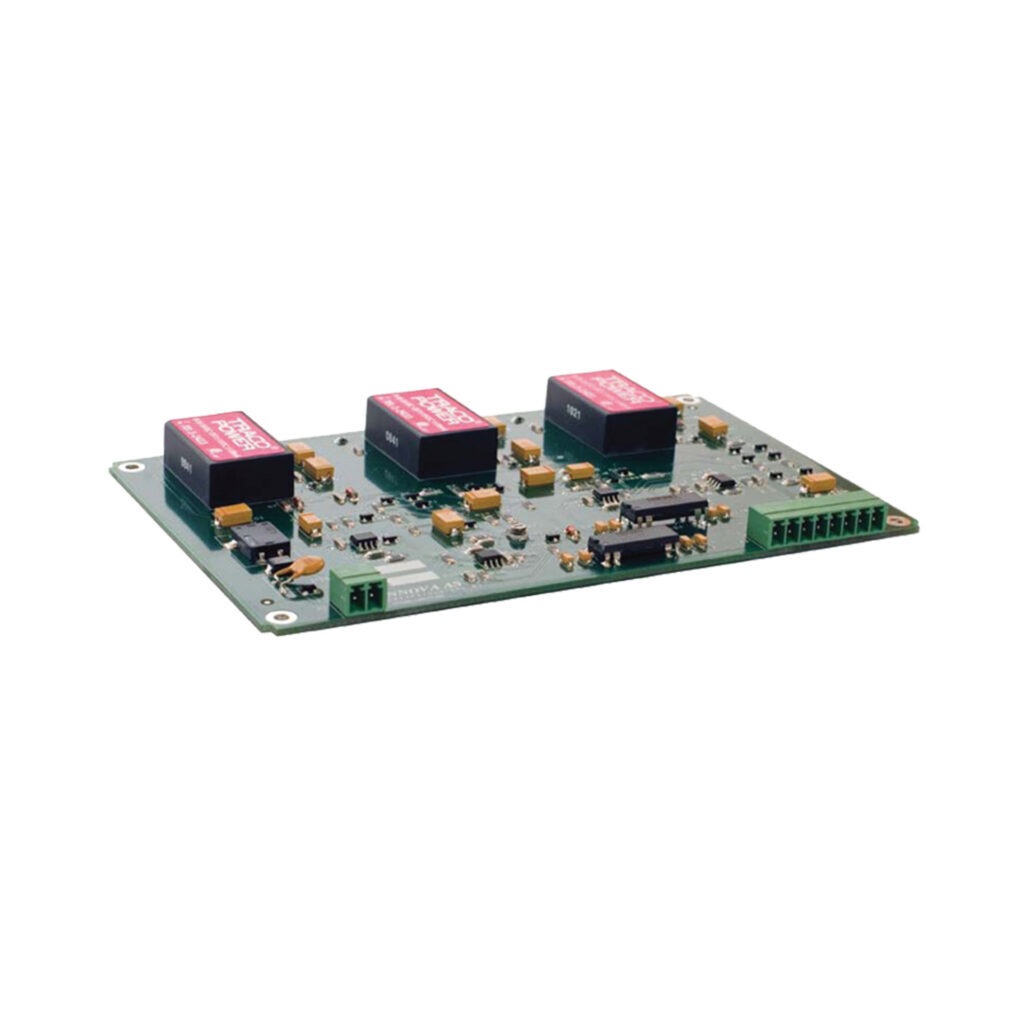

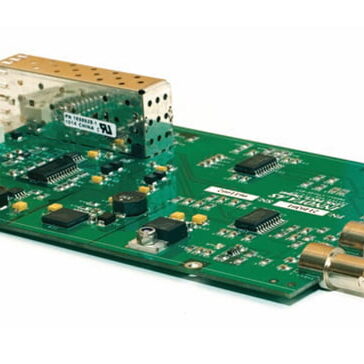

CUTE™ PWM 16 Valve Control Unit

PWM 16 is a compact intelligent valve controller capable of controlling up to 16 proportional valve functions, as well as pressure sensor monitoring. The unit is designed for mounting in oil-filled compensated enclosures, and pressure rated to 3000msw.

Description

The unit is ideal as the core system in ‘intelligent valve packs’ and the small size makes it an ideal way of upgrading and adding intelligence to existing units. This valve controller can act as a stand alone component, or as a part of a valve pack or a larger system. The unit is designed primarily to control 16 individual 24Vdc loads. The design allows the unit to be installed in a PWM 16 pressurized environment such as compensated, submerged oil-filled enclosures. Typical applications are operation of solenoid or proportional hydraulic valves. Control of proportional valves provided by 16 channels of pulse width modulated output.

The PWM 16 has digital adjustment of pulse characteristics, making it easy to tune the control signal to individual valves. In addition, the unit monitors four off 4-20mA sensors such as pressure or temperature sensors. Four isolated digital inputs are available and can be used to monitor end switches or other on/off switches. Remote control is possible via multidrop RS485 or RS232 serial link. The unit is configurated to act as a slave controller from a host system. Several PWM16 controllers (and other Cute units) can be controlled over a 485 network. The unit can be supplied with demonstration and test software and communications protocol documentation, making it easy to interface the PWM16 to any control system.

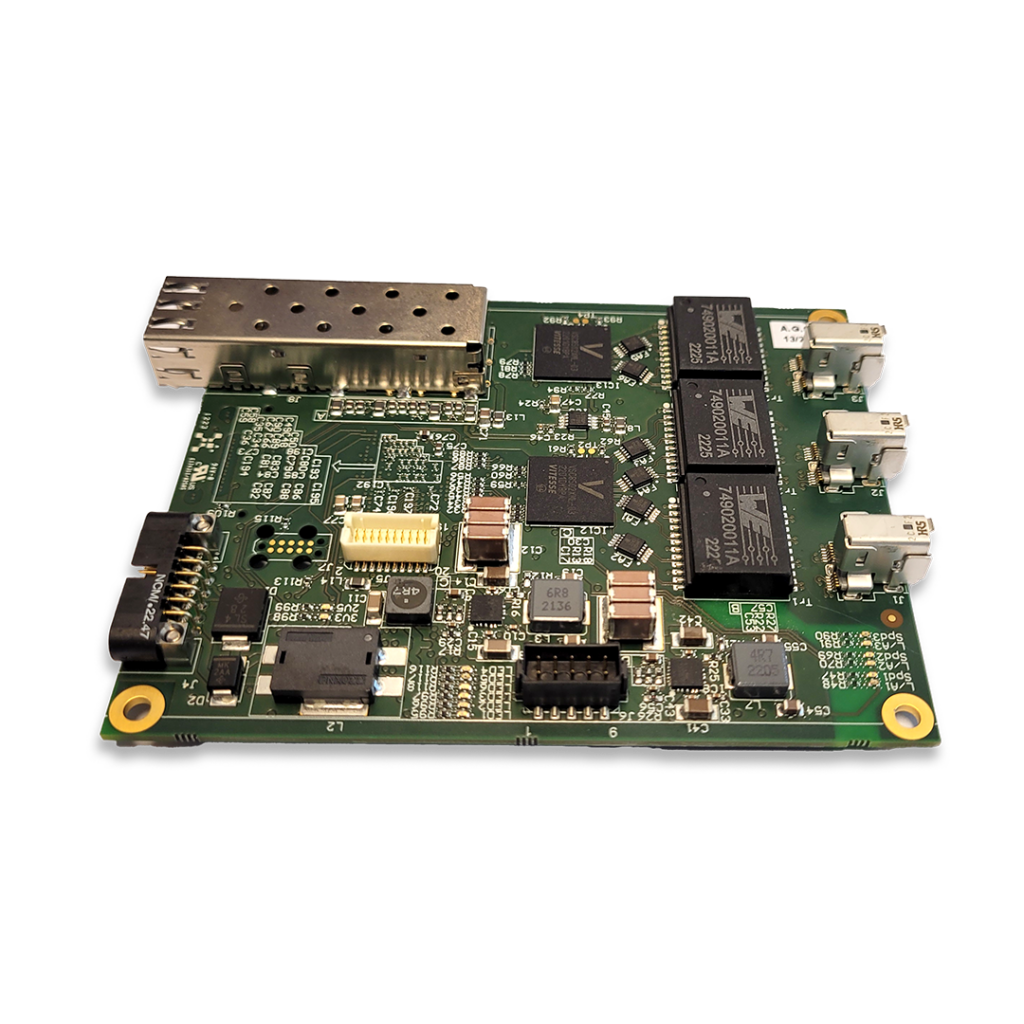

The PWM16 is still available for sale, but it has been replaced by the PIO36 in our designs. The PIO36 is Innova’s next generation of valve controller and our current recommendation for control systems.

Technical information

Physical IO configuration

• 16 x 24V PWM or on/off function 2A

• 6 x analogue inputs 4-20mA 10 bit resolution

• 4 x isolated digital inputs 24V

Software Features

• “Do All” function that read and write all I/O in one command

• Save default power-up values

• Flexible multiple read write I/O commands

• Demonstration and test software delivered with module (optional)

Size and mounting interface

• Size 87 x 112 x 21 mm

• Mounting 4 or 6 M3 bolts

• Housing Aluminium cover

Pressure tolerance

300 bar/3000m water depth

Terminals

• RS232 ICP 10 pin modem configured

• RS485 Screw terminals

• PWM outputs Screw terminals

• AnaIogue input Screw terminals

• Digital input Screw terminals

The optional PWM16 kit contains

• PWM16 module

• PC interface cable

• Documentation

• Demonstration and test software