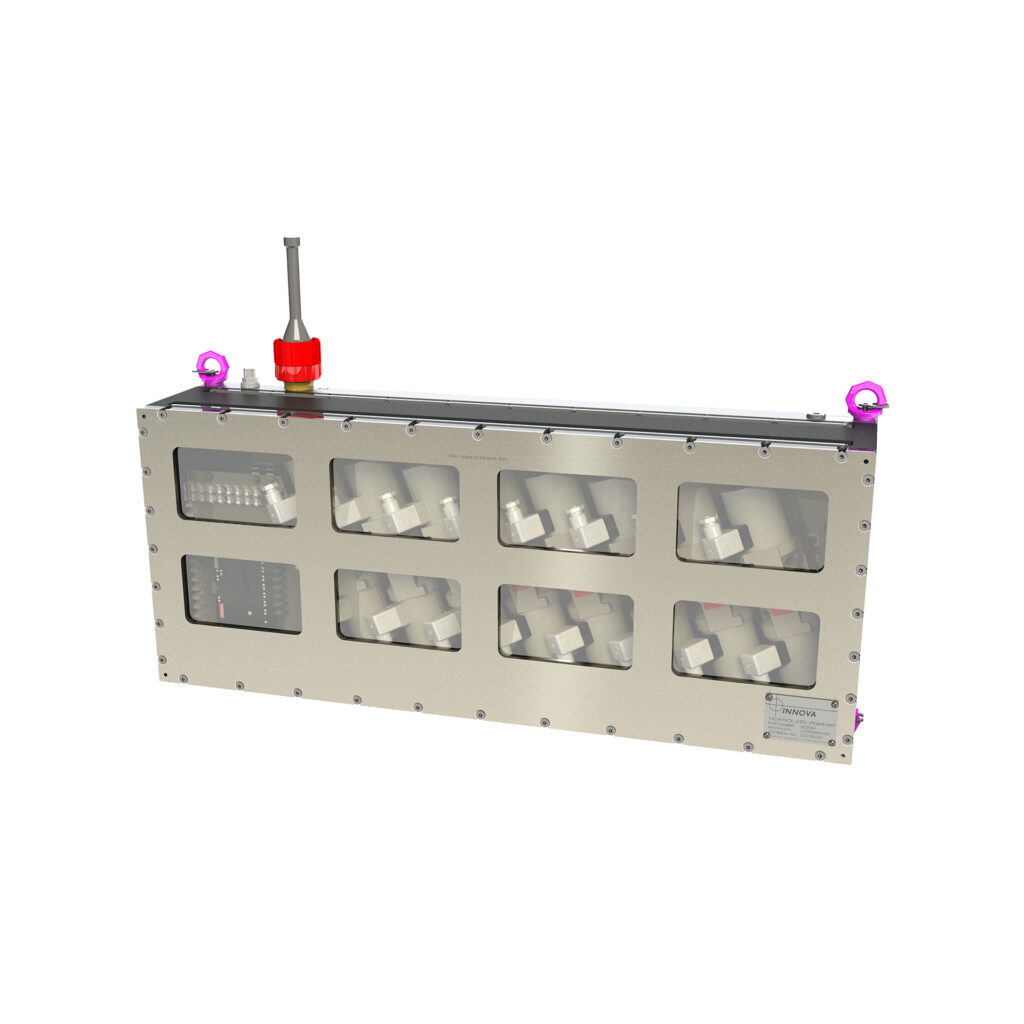

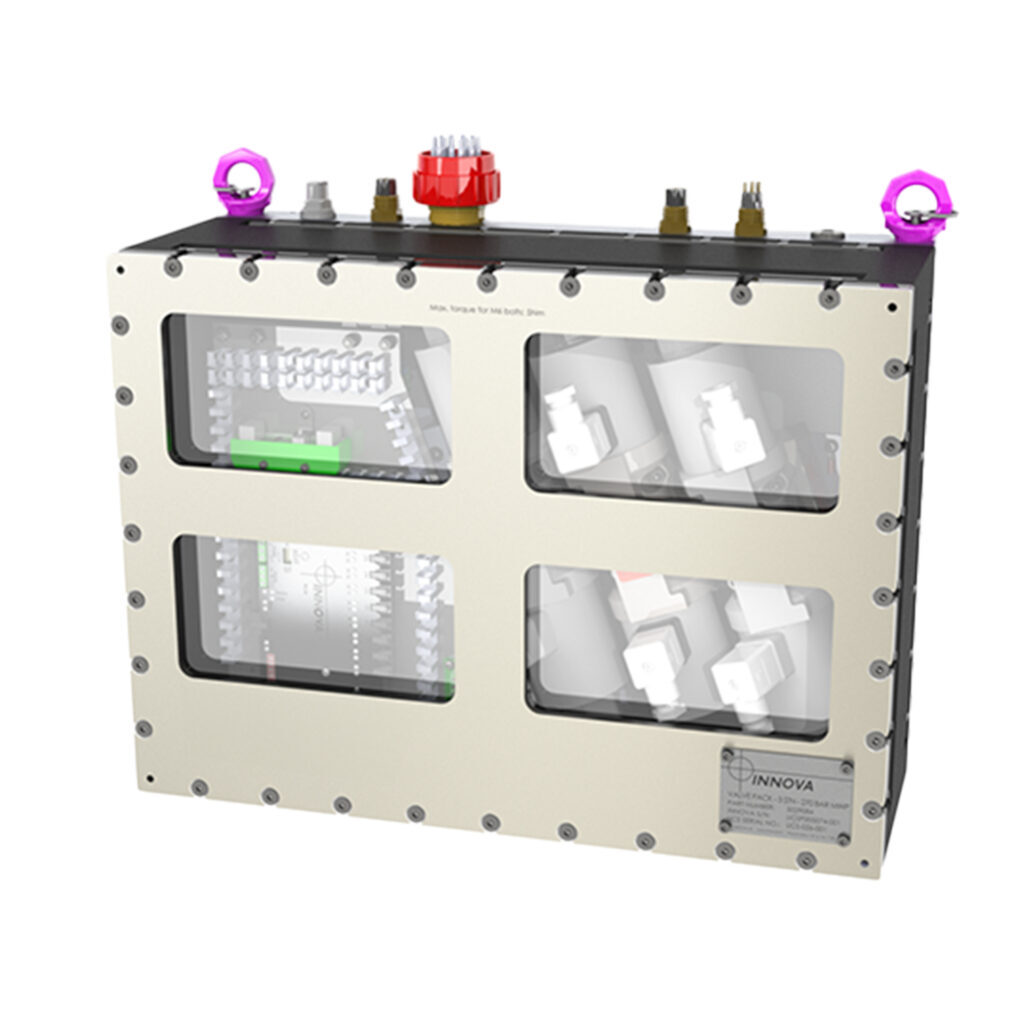

Valve Pack 11 Station

Subsea valve pack with up to 10 NG4 valves and 1 NG6 valve. Available with any combination of solenoid and proportional valves.

Description

Valve control and communication is provided by Innova´s PIO36 pressure tolerant controller boards, enabling full control of the subsea valve pack over an ethernet or a serial connection. The Innova Topside GUI software is used to control and monitor all functions of single or multiple valve packs, or the packs can easily integrate into an existing control system by using MODBUS over serial or Ethernet. The valve pack has a transparent lid and LED indicators on all functions, providing visual indication of operation during testing and diagnostics.

Key features

- Up to 10 off 4/3-way valves

- Solenoid and/or proportional valves

- Internal counterbalance valve for each proportional valve

- Proportional relief valve for pump control (NG6)

- Pressure and temperature transmitters

- Connectors for external equipment

- 3000 m depth rating

Technical information

Hydraulic Functions

Up to 10 off 4/3-way NG4 control valves & 1 off NG6 control valve.

- Design pressure: 250 bar

- Valve nominal flow: 30 lpm

- Pressure transmitters on the P and T ports

- Temperature transmitter on P port

Electrical

2 off Innova PIO36 pressure tolerant embedded controller with the following functionality on each card:

- 16 x 24 V PWM or on/off function – 2A per function

- 16 x analog inputs (16 bits ADC)

- 4 x isolated digital inputs 24 VDC

- Ethernet, RS232 or RS485 communication link

- Max power consumption: 10 A @ 24 VDC

- Water alarm

Interfaces

- G1/2 hydraulic supply and return (G3/8 secondary)

- G3/8 hydraulic output ports

- 1 x Burton type – 5506-2008 connector for power and communication

- 15 x MCBH type connectors for external equipment

Mechanical

- Hard anodized aluminium housing

- Polycarbonate lid

- Weight in air: 50 kg – In water: 22 kg

- Length x Width x Height: 540 x 276 x 192 mm (excl. connectors)

- External compensation

Software

Can be delivered with standard Innova software with graphical user interface to control each valve, read sensor values, calibrate sensors and log data. Our software engineers will also assist integration with existing control systems on request.